Professionally managed and an established name in the organized packaging sector of India, PentaPlus is a potent mix of the old infused with the new. Three decades of legacy of the printing and packaging industry has added volumes of experience to PentaPlus’s expertise. And, clubbed with this expertise is the energy and passion of a forward-thinking young team of printing experts, engineers and management professionals who come together to propel PentaPlus’s growth with innovative product lines and strong working systems.

Pentaplus has incorporated both technology and man skills to provide superlative services to our clients. Following are some of the policies which reflects our professional approach and workmanship.

Our Company policy is to provide Quality Products and Services to achieve Customer Satisfaction through

In order to achieve quality and manage them effectively, we at Pentaplus have invested time, effort and tools to achieve customer satisfaction every single time.

It is also our endeavor to learn ad share knowledge from what we have learnt. Thus we at our QC lab invested in instruments through which we are able to meet high standards of our clients ad measure quality at every step of our production process.

GSM is known as Grammage per square meter, which is an important factor in Paper and Packaging industry for measurement. GSM Scale is used to measure the GSM of paper through the weight of paper.

Tearing Strength Tester is a consistent tool useful to determine the tearing strength of fabrics, plastic films, and similar materials.

Bursting Strength Tester measures bursting strength of paper, paper board, and corrugated board. Bursting strength is a traditional measure of paper strength and it is also a test requirement for corrugated board.

Moisture meters are used to measure the percentage of water in a given substance. This information can be used to determine if the material is ready for use, unexpectedly wet or dry, or otherwise in need of further inspection.

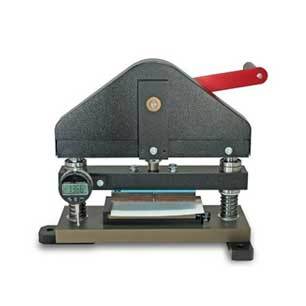

The Carton Board Creaser is used for testing the creasability of carton board. Ensures fault free folding, the Carton Board Creaser gives the board mill and the carton makes a ready and reliable method for checking the creasing qualities of carton boards.

COBB Tester determines water absorption of paper and other sheet materials. It measures the weight increase of a sample exposed to water in a given time. The test consists of a Test Apparatus, Roller and Blotting paper.

Stiffness Tester utilizes a two directional pendulum-type weighing system to evaluate material stiffness, flexural strength, resiliency and elasticity properties.

Tensile testing, is used to determine the behavior of a sample while an axial stretching load is applied. Tensile testing is commonly used to determine the maximum load (tensile strength) that a material or a product can withstand.

Measures the viscosity of the ink by flowing a definite volume of ink through the cup. The time (seconds) required for the ink to flow through the cup defines the viscosity of the ink.

X-Rite spectrophotometer offers the most precise, consistent, and reliable sample measurement. It help us achieve improved batch-to-batch color accuracy and faster time to market, while reducing rework and waste.